History and Features

BizenYaki pottery is crafted using Japan's oldest pottery making techniques. It first evolved from Sueki pottery, that was made in the Heian period. The Momoyama period (1568-1600), was the golden age of art in Japan. The great lord Toyotomi Hideyoshi and great tea master Sen no Rikyu both loved Bizen ware and greatly supported it. Many tea ware masterpieces were made during this period.

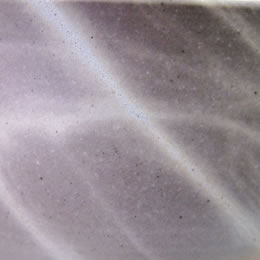

A key feature of Bizen ware is that the wood-burning firing process brings out the natural colors and tones of the clay. No applied glazes are used. Still today we use no chemical fuel, heating our kiln up to 1300 degrees over two weeks using only wood from Japanese red pines. Each piece displays a balance of natural beauty, originality and harmony. The natural elements ensure all of our pieces are both attractive and tasteful. The Bizen ware tradition also reflects Japanese artistic sensibilities with an emphasis placed on inner beauty and subtlety.

Although It takes much time, money and labor to make Bizen ware, Bizen ware has never stopped production for a thousand years. The more you use it, The better you understand it. If it's used daily, the color and gloss on it becomes much better and deeper like leather by absorbing oil from the hand and alcohol.

Moreover, Bizen has a miraculous power of making water and Sake tasty. If you pour beer into a Bizen cup, the bubbles become long lasting and fine- grained, so beer is pleasant to the taste. It also has a power of preserving fresh water, so flowers in Bizen vases are long lasting. This happens because of the unglazed surface of the ware. Bizen ware contains much iron in the clay, so it has excellent ability to retain heat or coolness. We can enjoy every drink at it's best.